- 15+ Years Grinding Solution Experience

- Customized Grinding Jar Design

- Imported Australia Zirconium Raw Material

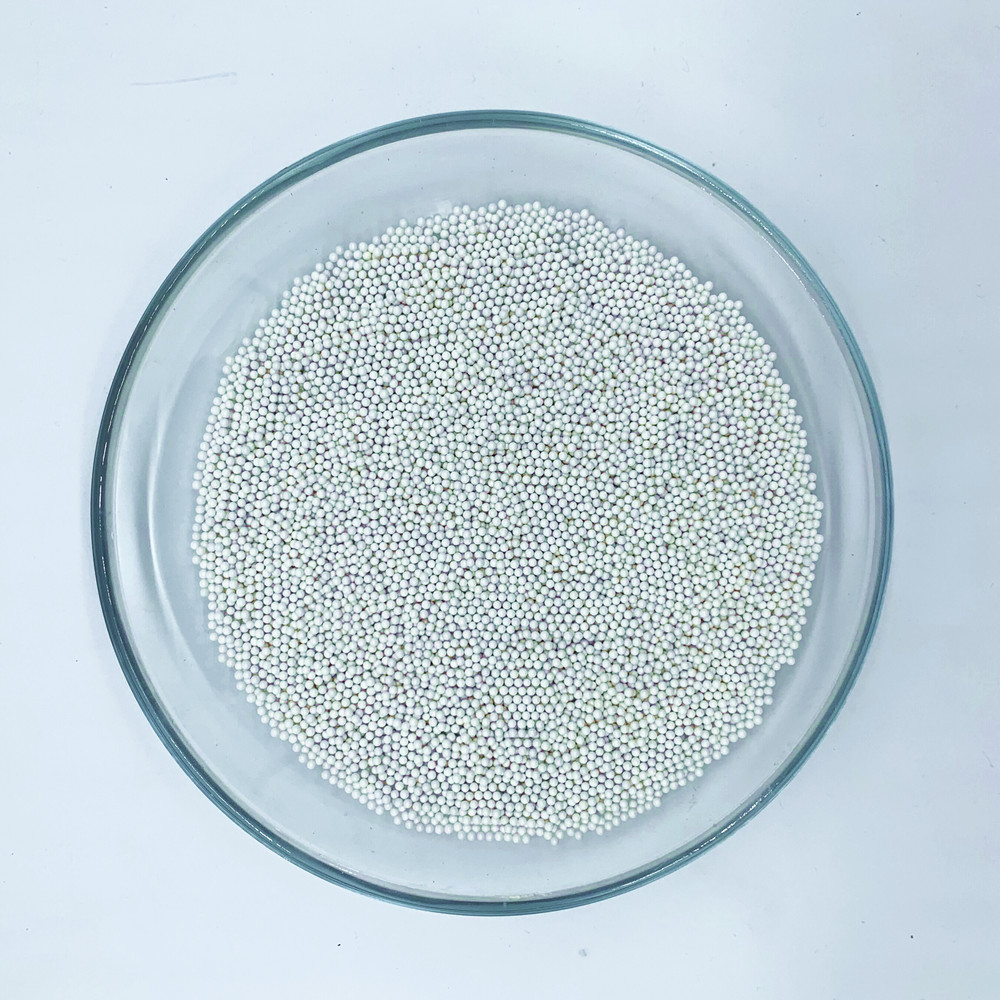

Zirconia Beads: An Efficient, Longer-Lasting & Virtually Contamination-Free Solution for Grinding & Milling

Kingda Ceramic has professionally served the nano and ultrafine grinding industry with yttria stabilized zirconia beads, ceria stabilized zirconia beads, 85 zironia beads,zirconium silicate beads, and all types of grinding media for over 15 years.

- High durability for extended lifespan

- Strong resistance to wear and corrosion.

- Enhanced stability for consistent performance.

- Superior performance in diverse applications.

- Call us : +86 15367874686

- Email : info@kingdacera.com

Yttria Stabilized Zirconia Beads

Ceria-stabilized Zirconia Beads

Brown Ceria Stabilized Zirconia Beads

85 Alumina Toughen Zirconia Beads

Zirconia Grinding Cylinders

Ceramic Ball Mill Jar

We offer a diverse selection of high-quality jars designed to cater to your specific grinding needs.

Customizable Solutions: We understand the importance of customization when it comes to grinding jars. Our ball mill grinding jars can be tailored to your requirements in terms of size, shape, and material composition. We work closely with you to deliver a customized grinding jar that optimizes your efficiency and achieves excellent results.

Reliable Quality: Our commitment to quality is unwavering. We source our grinding jars from trusted manufacturers known for their precision engineering and superior craftsmanship. You can rely on the durability and performance of our grinding jars for your grinding processes.

Zirconia Grinding Jar

Alumina Grinding Jar

Agate Grinding Jar

Tungsten Carbide Grinding Jar

Ceramic Milling Jars

Stainless Steel Grinding Jar

Zirconium Oxide Powder and YSZ Powder Manufacturers

zirconium oxide powder includes cubic and monoclinic zirconia powder, offers a wide range of applications in multiple industries. With Tosoh Corporation being a leading manufacturer, high-quality zirconium oxide powders are readily available for various purposes. Zirconia powder and yttria stabilized zirconia powder can be used as a diamond simulant, and have wide applicaions fileds ,such as in ceramic components, or in fuel cells,thermal barrier,biomedical ceramics, functional ceramics,etc. zirconium oxide powder proves to be a valuable material with its exceptional properties and versatile applications.

3mol Yttria Stabilized Zirconia (YSZ) Powder

4mol Yttria Stabilized Zirconia (YSZ) Powder

5mol/8mol Yttria Stabilized Zirconia Powder

Get Your Custom Grinding Jars

Kingda is a trusted grinding jar manufacturer with years of experience in creating high-quality grinding solutions for various industries. It specializes in manufacturing high-quality custom ball mill jars to cover various needs of customers. Here are your custom selections:

Get Your Custom Grinding Jars

Kingda is a trusted grinding jar manufacturer with years of experience in creating high-quality grinding solutions for various industries. It specializes in manufacturing high-quality custom ball mill jars to cover various needs of customers. Here are your custom selections:

Design is another aspect of our ball mill jars can be tailored to your needs. Whether you have an existing design that you would like us to replicate or you need a new design to be created from scratch, we have the expertise to provide a custom design to meet your requirements

We can supply cylindrical,rectangular,spherical, conical,irregular planetary ball mill jar and rolling ball mill jar.

We have designed for Retsch ball mill,disc mills,FritschPulversette5/6/7,different lab milling equipments around the world.

We can offer customization of the different materials for laboratory jar mill, including zirconia ball mill jar,alumina jar rolling mill,tungsten carbide milling jar,agate ball mill jar,porcelain ball mill jars,stainless steel grinding jar.

Zirconia Grinding Jar Manufacturing Process

1):Raw Material Preparation:

The main raw material used for zirconia grinding jars is yttrium stabilized zirconium oxide powder which is also known as 3mol YSZ powder. The powder is typically obtained by mining and refining zirconium minerals. The zirconia powder is carefully selected for its purity and desired properties.

2):Forming:

The zirconia powder is mixed with other additives, such as stabilizers and binders, to enhance its properties and facilitate the shaping process. The mixture is typically wet milled or ball milled to achieve a homogeneous blend. The resulting paste-like material is then formed into the desired shape of the grinding jar using various techniques such as cold isostatic press (CIP) or injection molding.

3):Sintering is a crucial step in the manufacturing

process where the zirconia grinding jar is heated to a high temperature, typically about 1400°C-1480°C (2372°F-2696°F-). The high temperature causes the zirconia particles to fuse together, resulting in a dense and solid structure. The sintering process also helps in achieving the desired mechanical strength ,density and hardness of the zirconia milling jar.

4): Polishing:

Once the grinding jar is sintered, it undergoes various finishing and polishing processes to achieve the final desired shape, dimensions, and surface quality. This process will involve machining, grinding, and polishing to ensure the jar meets the required specifications.

5):Quality Control:

Throughout the manufacturing process, quality control measures are implemented to ensure that the zirconia grinding jars meet the desired standards. This can involve inspections, dimensional measurements, and testing of mechanical and chemical properties.

6):Packaging:

Finally, the finished zirconia grinding jars are carefully packaged to protect them during transportation and storage. They will be packaged by wooden or carton box.

What Our Other Customers Say About Us

Recent Projects of Customized Grinding Jars

Tungsten Carbide Grinding pot Compatible for Retsch Grinding Jar

Agate Grinding Jar Compatable For Retsch RS200

50ml Zirconia Milling Jar For Turkey

Zirconia Grinding Jars For Retsch PM200 PM400

Frequently Asked Question

What Certifications do you have?

CE, TUV,SGS

What's your production lead time for customized ball mill jars??

40-50 days for regular order. In case of urgent order, we try our best to finish in one month.

What is your nearest Port?

The nearest Port is Shanghai, Shenzhen and Guangzhou.

Do you provide samples ? Is it free or extra ?

Yes, we could offer the grinding beads,zirconia powder for free charge, but do not pay the cost of freight.

If the quality can not meet the requirement or any loss during the freight, how should we do?

We have strict QC test and professional QC team. We are always offering qualified zirconia beads,grinding jars,zirconia oxide powder,customized zirconia parts. If anything goes wrong, the quality can not meet requirement on the contract, we will reproduce the qualified products or refund the payment. We have the professional packing team and will pack the product in safe package for long distance delivery. If any loss during the freight, we hope you can assistant us to claim from the logistics company and we will arrange the replacement accordingly.