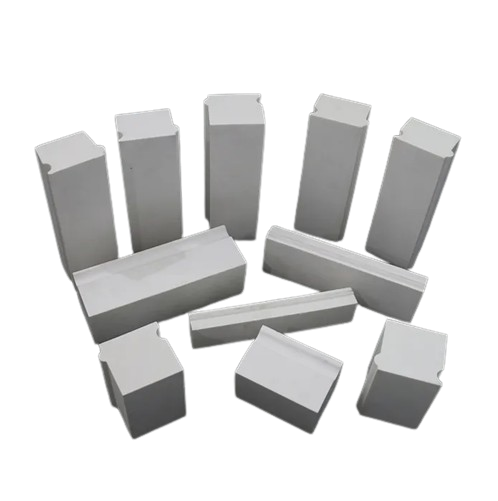

1: As ceramic grinding media,tools and abrasives, they are used in different industries,the primary purpose of ceramic ballsis to grind coarse materials into micrometers or ultrafine particles.

Bead Mills, Ball Mills, Attritors, Sand Mills, Pearl Mills, Vibrating Energy Mills, High-Speed Dispersers, Planetary Ball Mills Polishing Equipment,etc.

Ceramic balls serve a multitude of purposes across various industries due to their unique properties and advantages. From grinding usage,precision bearings to chemical processing, their applications are diverse and essential.

As manufacturing ceramic grinding balls in China and provide milling solutions for the past 15 years, our ceramic balls serve as grinding media, effectively reducing particle size and achieving fine dispersion of materials. Their superior hardness and wear resistance enable them to endure the abrasive conditions of grinding processes, resulting in consistent particle size reduction and high-quality end products. Ceramic balls find application in industries ranging from ceramics and mining to paints and pigments, where particle size control is critical for product performance and quality.

Ceramic grinding media includes a range of abrasive materials used in various industrial processes, each tailored to specific applications and requirements. Ceramic balls also called porcelain balls,ceramic milling media, or ceramic beads, and encompasses different material,such as alumina beads,silicon nitride ceramic balls and zirconia milling media, these ceramic materials offer superior performance in grinding and milling operations.

Alumina milling media, composed of high-purity alumina ceramic, is renowned for its exceptional hardness and wear resistance.Ceramic balls for ball mills are a common form of ceramic grinding media, utilized in both wet and dry milling operations and widely used in ball mills and grinding equipment. alumina milling media efficiently crushes and disperses particles to achieve desired particle sizes and distributions in various materials processing applications.

Zirconia milling media also called ysz zirconia beads, featuring zirconium oxide as the primary component, offers superior toughness and fracture resistance compared to other ceramic materials. This makes it ideal for high-impact grinding applications, such as in ball mills and attritors, where intense milling forces are encountered. Zirconia beads also called zirconium oxide beads ,and it ensures consistent, high-quality results in particle size reduction and dispersion processes.

These spherical beads provide efficient grinding action, reducing particle size and promoting particle dispersion in slurries or dry powders. Ceramic balls for ball mills are available in various compositions, including 92% alumina balls, renowned for their high density and abrasion resistance, ensuring extended service life and minimal media wear.

Ceramic grinding media play a crucial role in material processing operations, offering a range of options tailored to specific applications and processing requirements. From porcelain beads to alumina and zirconia milling media, these abrasive materials ensure efficient particle size reduction, dispersion, and surface finishing across various industries.

Full name of zirconium oxide beads is yttrium stabilized zirconia beads/balls, also called YSZ zirconia beads,zirconia grinding balls,zirconia milling beads, ZrO2 beads,zirconia grinding media, zirconium oxide grinding balls, and zirconia ceramic beads,etc.

These beads are composed of zirconium oxide, a highly durable and wear-resistant material known for its exceptional hardness and thermal stability.

Zirconium oxide beads are commonly employed in grinding and milling processes to achieve fine particle size reduction and dispersion. Their high density and superior toughness make them ideal for use in high-impact grinding equipment such as ball mills, attritors, and bead mills. Zirconium oxide beads efficiently crush and disperse particles, resulting in uniform particle size distributions and enhanced product quality.

One of the key advantages of zirconium oxide beads is their resistance to abrasion and chemical corrosion. This allows them to withstand harsh operating conditions and abrasive materials, ensuring long-lasting performance and minimal media wear. Additionally, zirconia oxide grinding beads offer high thermal conductivity, making them suitable for applications involving high-temperature processing environments.

In industries such as ink, ceramics, paints, coatings, and pigments, new energy batteries,zirconium oxide beads are widely utilized for their ability to achieve precise particle size control and consistent results. They are also commonly used in pharmaceutical and biotechnology applications for the micronization of active pharmaceutical ingredients (APIs) and drug formulations.

Zirconia beads are primarily composed of 95% zirconium dioxide (ZrO2) and 5% yttria (Y2O3) .Its main usage is for grinding, dispersing and polishing.

Cubic zirconia beads typically refer to artificial gemstones used in jewelry making, which mimic the appearance of diamonds but at a lower cost. These beads are synthesized chemically and are composed of zirconium oxide. They are commonly used to make earrings, necklaces, bracelets, and other accessories, and are favored by consumers for their aesthetic appeal and durability.

On the other hand, zirconia grinding beads are industrial abrasive materials used for grinding, crushing, dispersing materials. These beads are often utilized in high-speed grinders, ball mills, and grinding equipment for processing ceramics, coatings, pigments, cosmetics, and other materials. Unlike cubic zirconia beads, zirconia grinding beads are typically not used for jewelry making but rather for grinding and dispersing operations in industrial processing.

The material used for synthesizing cubic zirconia diamonds and zirconia grinding beads is essentially the same, as both are made from zirconium oxide (ZrO2). However, the manufacturing processes and specific formulations may vary depending on the intended application.

For cubic zirconia diamonds, it is also called ceramic beads for jewelry making (porcelain beads for jewelry making), the focus is on creating gem-quality synthetic stones that closely resemble natural diamonds in appearance. The synthesis process involves carefully controlling the crystal structure and composition of zirconium oxide to achieve the desired optical properties, such as clarity and brilliance. Additional dopants or additives may be included to enhance color or modify other characteristics.

On the other hand, zirconia grinding beads are engineered for industrial applications where hardness, wear resistance, and abrasive properties are paramount. While they are still made primarily from zirconium oxide, the manufacturing process may involve additional steps to optimize properties such as hardness, toughness, and shape uniformity for efficient grinding and milling operations. Stabilizing agents or modifiers may also be incorporated to enhance performance in specific applications.

In summary, while the basic material for both cubic zirconia diamonds and zirconia grinding beads is zirconium oxide, the processing and formulation are tailored to meet the distinct requirements of their respective applications.

Yes, zirconia grinding beads can be used for polishing purposes in mass finishing machines,vibration polishing machine barrel finishing machines, or tumbling machines. These machines are commonly used for surface finishing, deburring, and polishing of metal, plastic, and ceramic parts.

Zirconia grinding beads are well-suited for polishing applications due to their high hardness, wear resistance, and abrasive properties. When used in mass finishing or tumbling machines, zirconia beads efficiently remove burrs, sharp edges, and surface imperfections from workpieces, resulting in smooth, polished surfaces. They can effectively polish a wide range of materials, including metals, plastics, and ceramics, to achieve desired surface finishes and textures.

Additionally, zirconia grinding beads offer consistent performance and long service life, making them ideal for continuous polishing operations in mass finishing processes. Their durability ensures minimal media wear and extended reusability, resulting in cost-effective polishing solutions for various industries, including automotive, aerospace, jewelry, and manufacturing.