Zirconia Beads: An Efficient, Longer-Lasting & Virtually Contamination-Free Solution for Grinding & Milling

Kingda Ceramic has professionally served the nano and ultrafine grinding industry with zirconia beads, including yttria stabilized zirconia beads, ceria stabilized zirconia beads, 85 zironia beads, Zirconia Alumina Composite Bead,zirconium silicate beads, and all types of ceamic grinding media for over 18 years.

- Used as ultrafine grinding, dispersing and polishing

- High specific gravity of zirconia beads are wear resistant

- Fine polishing media zirconia balls can be used in stirred mills, horizontal mills,bead mills,planetary ball mill,vibratory mills

- Beads available in sizes from 0.1mm to 50mm diameter

Yttria Stabilized Zirconia Beads

The yttria stabilized zirconia beads is called as zirconia beads with high specific gravity. It includes with 95 percent of zirconia oxdie content and the remaining 5 percent is yttria as stabilizer.High strength, wear resistant and corrosion resistance.

Ceria Stabilized Zirconia Beads

Ceria stabilized zirconia beads is nearly same as ysz balls.Withstand high temperatures and harsh chemical environments,low thermal expansion,can be used for dry and wet grinding

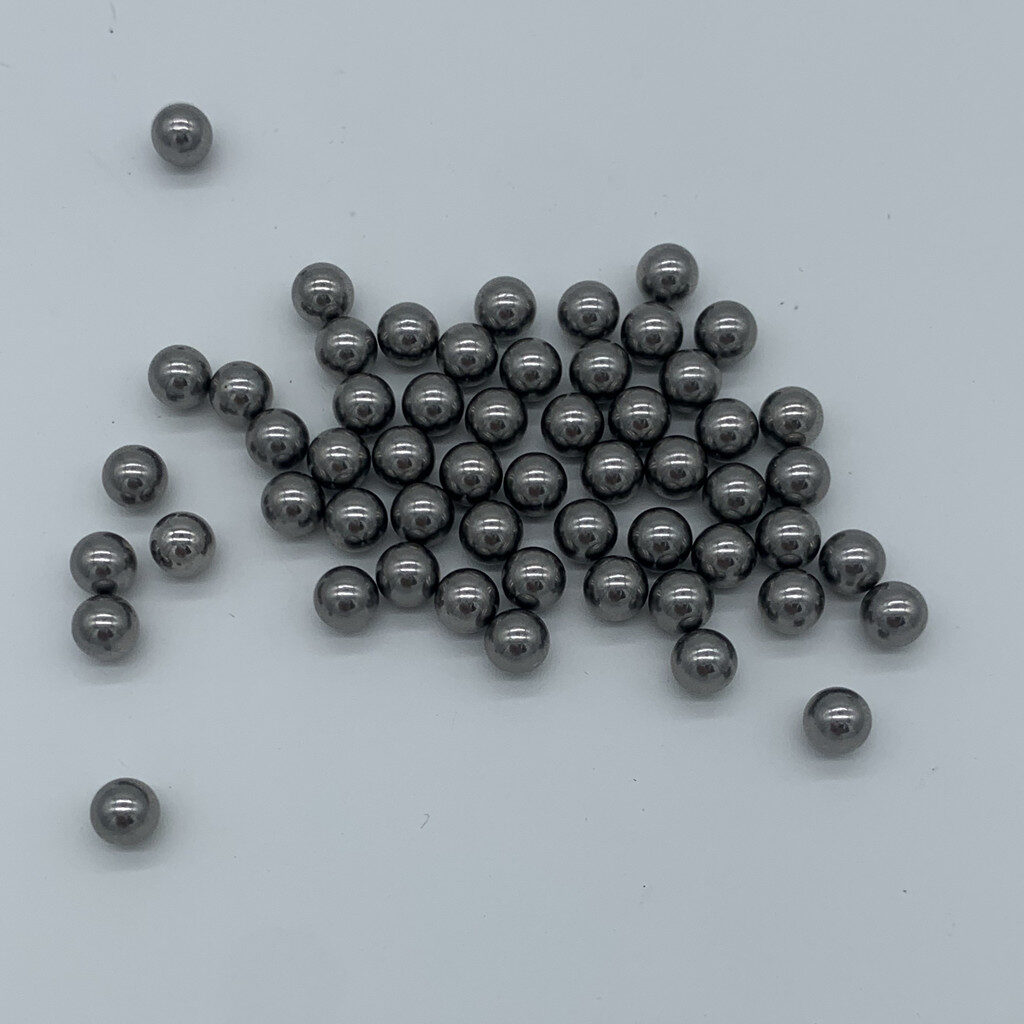

Black CZ Beads

Black cerium-stabilized zirconia beads: high density, excellent chemical and thermal stability, versatile for various applications, and extreme contamination. They offer superior performance in particle size reduction.

Zirconia Alumina Composite Bead

The zirconia-alumina composite sphere consists of a mixture of 85% zirconium and 10% alumina. Zirconium, a highly refractory metal, imparts excellent heat resistance and corrosion resistance to the composite. Alumina, on the other hand, enhances the overall strength of the sphere.

Zriconium Silicate Beads

Zirconium silicate beads (ZrSiO4) is reffered as zirconia silica beads which are chemically stable, wear-resistant. These beads are extensively used as grinding media in ceramics, paints, coatings, and pharmaceuticals,Pesticides ,fertilizers and balancing beads.

Agate Balls

The agate grinding balls has good crushing performance and is wear-resistant. At the same time, the surface of the agate material is very smooth and has no friction effect, which avoids sample residue and does not cause cross contamination. It is better than brass or hard porcelain mortars.

Silicon Nitride Balls/Si3N4 Balls

Silicon nitride balls, also known as Si3N4 balls, are composed of silicon nitride (Si3N4), a high-performance ceramic material. These balls offer exceptional properties, including high hardness, excellent wear resistance, and superior thermal stability. They are widely used as grinding, precision bearings, valves, and other high-temperature and high-stress applications.

Tungsten Carbide Beads

Tungsten Carbide Beads are composed of tungsten carbide (WC), a high-density and extremely hard material,second only to diamond in hardness. Ideal for use in industries such as mining, oil drilling, and precision machining, tungsten carbide beads provide efficient material processing and extended tool life.

Stainless Steel Grinding Balls

Stainless Steel Grinding Balls are made of stainless steel, a corrosion-resistant alloy composed of iron, chromium, and other elements. These steel balls offer high hardness, and chemical stability. With their diverse properties, they are widely used in grinding and milling applications across industries such as pharmaceuticals, ceramics, and food processing.

Zirconium OXide Powder & YSZ powder

Kingda Ceramic manufactures a wide variety of zirconium oxide powder and yttria stabilized zirconia powder, which include monoclinic zirconia powder,plasma spray powder,3 mol yttria stabilized zirconia.All our ceramic powder are of high quality and high purity.

Check All Our Products

Frequently Asked Question for Zirconia Beads

What is the MOQ for ceramic ziconia beads media?

Our MOQ is 1kg for each size and type.

What is the packaeg of zirconia beads?

Our normal package is 25kg per plastic bucket and 12 buckets or more bucktes will make one pallet.

What is the Production Lead Time?

If it is sample order below 50kg, then 1 working day.

For bulk order, over 300 kilograms. then 5working days.

We also can reduce the time in case of any emergency.

How To Make The Payment?

You can make payment through different options like bank transfer, Money gram, Western Union, PayPal, alibaba online trading on the platform.

We also accept L/C on bulk orders.

What' your Nearest Port Details

Our nearest ports are Shenzhen,Guanzhou and Shanghai .

Zirconia Beads Introduction

Zirconia beasd are referred as yttria stabilized zirconia beads/balls, the perfect solution for your ball milling needs. These precision-engineered ceramic balls are designed to provide superior grinding efficiency and wear resistance, making them ideal for a variety of applications,such as milling,dispersing and polishing.

Our zirconia Balls are manufactured using titration forming,rolling and CIP press technology and premium materials to ensure superior performance and reliability. The unique composition of 5% yttria as stabilizer and 95% zirconia increases hardness, toughness and chemical resistance, making these balls highly durable and long-lasting. Whether you are grinding, dispersing or mixing materials, our zirconia beads deliver consistent, reliable results.

One of the main advantages of our yttria-stabilized zirconia balls is their high density, which allows for efficient grinding and reduced contamination. This makes them particularly suitable for use in ball mills to effectively grind and homogenize a variety of materials, including ink,painting,paper-making, coating,minerals, pigments and ceramics,new energy,lithium batteries.etc Additionally, its low wear rate ensures minimal maintenance and a longer service life, saving you time and money in the long run. Our zirconia balls are available in a variety of sizes to suit your specific requirements and can be customized to meet your exact specifications. Whether you work in the pharmaceutical, chemical or food industry, our yttria-stabilized zirconia balls are designed to meet the highest quality and performance standards.

Yttria-stabilized zirconia balls produced by kingda Ceramic are the perfect choice for anyone looking for reliable, high-performance grinding media for ball milling applications. Offering superior durability, wear resistance and efficiency, these balls are sure to increase the productivity and quality of your processes. Trust our zirconia balls to deliver outstanding results and take your grinding operation to the next level.

Zirconia Beads FRQ Guide

1.What are ceramic balls used for?

Ceramic balls serve a multitude of purposes across various industries due to their unique properties and advantages. From grinding usage,precision bearings to chemical processing, their applications are diverse and essential.

As manufacturing ceramic grinding balls in China and provide milling solutions for the past 15 years, our ceramic balls serve as grinding media, effectively reducing particle size and achieving fine dispersion of materials. Their superior hardness and wear resistance enable them to endure the abrasive conditions of grinding processes, resulting in consistent particle size reduction and high-quality end products. Ceramic balls find application in industries ranging from ceramics and mining to paints and pigments, where particle size control is critical for product performance and quality.

2.What is ceramic grinding media?

Ceramic grinding media includes a range of abrasive materials used in various industrial processes, each tailored to specific applications and requirements. Ceramic balls also called porcelain balls,ceramic milling media, or ceramic beads, and encompasses different material,such as alumina beads,silicon nitride ceramic balls and zirconia milling media, these ceramic materials offer superior performance in grinding and milling operations.

Alumina milling media, composed of high-purity alumina ceramic, is renowned for its exceptional hardness and wear resistance.Ceramic balls for ball mills are a common form of ceramic grinding media, utilized in both wet and dry milling operations and widely used in ball mills and grinding equipment. alumina milling media efficiently crushes and disperses particles to achieve desired particle sizes and distributions in various materials processing applications.

Zirconia milling media also called ysz zirconia beads, featuring zirconium oxide as the primary component, offers superior toughness and fracture resistance compared to other ceramic materials. This makes it ideal for high-impact grinding applications, such as in ball mills and attritors, where intense milling forces are encountered. Zirconia beads also called zirconium oxide beads ,and it ensures consistent, high-quality results in particle size reduction and dispersion processes.

These spherical beads provide efficient grinding action, reducing particle size and promoting particle dispersion in slurries or dry powders. Ceramic balls for ball mills are available in various compositions, including 92% alumina balls, renowned for their high density and abrasion resistance, ensuring extended service life and minimal media wear.

Ceramic grinding media play a crucial role in material processing operations, offering a range of options tailored to specific applications and processing requirements. From porcelain beads to alumina and zirconia milling media, these abrasive materials ensure efficient particle size reduction, dispersion, and surface finishing across various industries.

3.What is zirconium Oxide Beads?

Full name of zirconium oxide beads is yttrium stabilized zirconia beads/balls, also called YSZ zirconia beads,zirconia grinding balls,zirconia milling beads, ZrO2 beads,zirconia grinding media, zirconium oxide grinding balls, and zirconia ceramic beads,etc.

These beads are composed of zirconium oxide, a highly durable and wear-resistant material known for its exceptional hardness and thermal stability.

Zirconium oxide beads are commonly employed in grinding and milling processes to achieve fine particle size reduction and dispersion. Their high density and superior toughness make them ideal for use in high-impact grinding equipment such as ball mills, attritors, and bead mills. Zirconium oxide beads efficiently crush and disperse particles, resulting in uniform particle size distributions and enhanced product quality.

One of the key advantages of zirconium oxide beads is their resistance to abrasion and chemical corrosion. This allows them to withstand harsh operating conditions and abrasive materials, ensuring long-lasting performance and minimal media wear. Additionally, zirconia oxide grinding beads offer high thermal conductivity, making them suitable for applications involving high-temperature processing environments.

In industries such as ink, ceramics, paints, coatings, and pigments, new energy batteries,zirconium oxide beads are widely utilized for their ability to achieve precise particle size control and consistent results. They are also commonly used in pharmaceutical and biotechnology applications for the micronization of active pharmaceutical ingredients (APIs) and drug formulations.

4.What are zirconia beads made of?

Zirconia beads are primarily composed of 95% zirconium dioxide (ZrO2) and 5% yttria (Y2O3) .Its main usage is for grinding, dispersing and polishing.

5.What's the difference of zirconia beads and cubic zirconia beads?

Cubic zirconia beads typically refer to artificial gemstones used in jewelry making, which mimic the appearance of diamonds but at a lower cost. These beads are synthesized chemically and are composed of zirconium oxide. They are commonly used to make earrings, necklaces, bracelets, and other accessories, and are favored by consumers for their aesthetic appeal and durability.

On the other hand, zirconia grinding beads are industrial abrasive materials used for grinding, crushing, dispersing materials. These beads are often utilized in high-speed grinders, ball mills, and grinding equipment for processing ceramics, coatings, pigments, cosmetics, and other materials. Unlike cubic zirconia beads, zirconia grinding beads are typically not used for jewelry making but rather for grinding and dispersing operations in industrial processing.

6.Does cubic zirconia beads used for synthesizing zirconia diamonds and zirconia grinding beads use the the same material of ZrO2?

The material used for synthesizing cubic zirconia diamonds and zirconia grinding beads is essentially the same, as both are made from zirconium oxide (ZrO2). However, the manufacturing processes and specific formulations may vary depending on the intended application.

For cubic zirconia diamonds, it is also called ceramic beads for jewelry making (porcelain beads for jewelry making), the focus is on creating gem-quality synthetic stones that closely resemble natural diamonds in appearance. The synthesis process involves carefully controlling the crystal structure and composition of zirconium oxide to achieve the desired optical properties, such as clarity and brilliance. Additional dopants or additives may be included to enhance color or modify other characteristics.

On the other hand, zirconia grinding beads are engineered for industrial applications where hardness, wear resistance, and abrasive properties are paramount. While they are still made primarily from zirconium oxide, the manufacturing process may involve additional steps to optimize properties such as hardness, toughness, and shape uniformity for efficient grinding and milling operations. Stabilizing agents or modifiers may also be incorporated to enhance performance in specific applications.

In summary, while the basic material for both cubic zirconia diamonds and zirconia grinding beads is zirconium oxide, the processing and formulation are tailored to meet the distinct requirements of their respective applications.

7.Can zirconia grinding beads be used for polishing purposes in the mass finishing machine, vibro finishing machines, barrelling machine or tumbling machine?

Yes, zirconia grinding beads can be used for polishing purposes in mass finishing machines,vibration polishing machine barrel finishing machines, or tumbling machines. These machines are commonly used for surface finishing, deburring, and polishing of metal, plastic, and ceramic parts.

Zirconia grinding beads are well-suited for polishing applications due to their high hardness, wear resistance, and abrasive properties. When used in mass finishing or tumbling machines, zirconia beads efficiently remove burrs, sharp edges, and surface imperfections from workpieces, resulting in smooth, polished surfaces. They can effectively polish a wide range of materials, including metals, plastics, and ceramics, to achieve desired surface finishes and textures.

Additionally, zirconia grinding beads offer consistent performance and long service life, making them ideal for continuous polishing operations in mass finishing processes. Their durability ensures minimal media wear and extended reusability, resulting in cost-effective polishing solutions for various industries, including automotive, aerospace, jewelry, and manufacturing.